Our A308 piston seals are made up of a special low friction coefficient carbon PTFE material and NBR energizing ring combination.

Instead of an O-ring, as an energizing ring, a more durable square ring is used to prevent reverse or twisted assembly thanks to our special design.

They are used safely at high sliding speeds due to the very low friction force, which is one of the superior features of PTFE material.

A308 can be combined with FKM square ring for special needs, meeting temperature and chemical resistance requirements.

| TECHNICAL DATA |

| Working Pressure |

400 Bar |

| Working Temperature |

-30/+105°C |

| Sliding Speed |

5 m/sn |

| Material |

PTFE + CARBON / 80 NBR |

| Media |

Mineral Base Hydraulic Oil |

| Surface Roughness |

| |

Ra |

Rmax |

| Dynamic Surface |

≤0.2 µm |

≤2.0 µm |

| Groove Base |

≤1.6 µm |

≤6.3 µm |

| Groove Flanks |

≤3.2 µm |

≤15.0 µm |

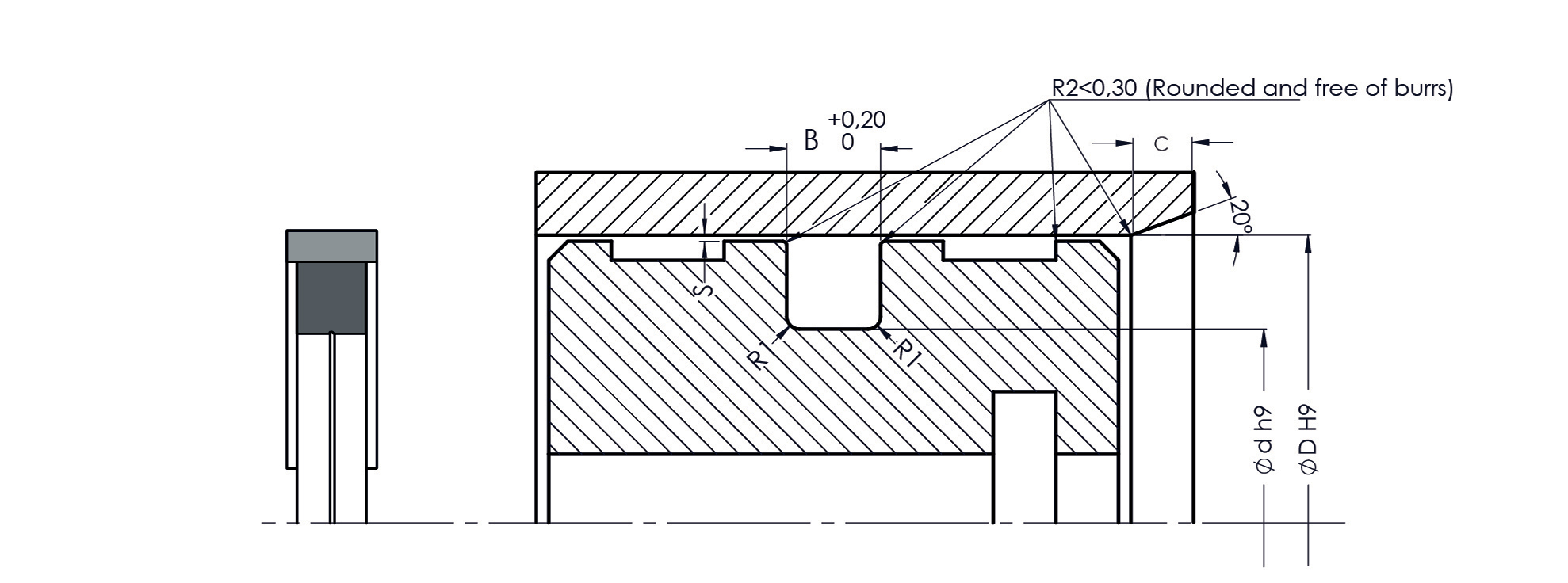

| Permissible Gap (S Max.) |

| Housing Length (B) |

Pressure (bar) |

| 150 |

250 |

400 |

| 7.5 |

0.40 |

0.30 |

0.25 |

| 8 |

0.40 |

0.30 |

0.30 |

| 9 |

0.60 |

0.50 |

0.25 |

| 10 |

0.70 |

0.50 |

0.30 |

| 16 |

0.70 |

0.50 |

0.35 |