A122

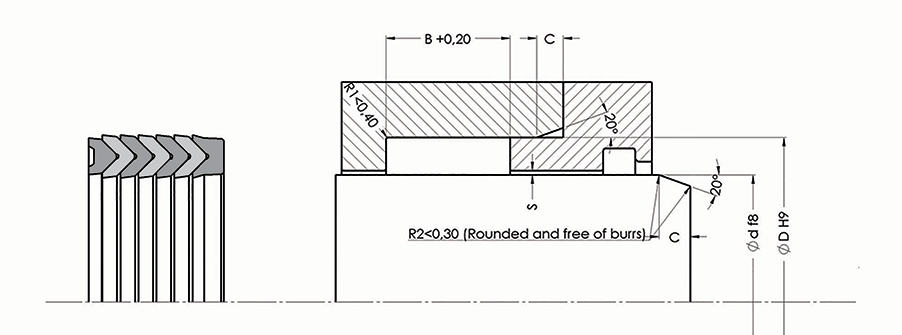

| ALP NO | DIMENSION | Ød | ØD | B | C |

|---|---|---|---|---|---|

| A122-012 | 12,7X25,4X19,05 | 12,7 | 25,4 | 19,05 | 4 |

| A122-019 | 19,05X28,5X17,46 | 19,05 | 28,5 | 17,46 | 4 |

| A122-020 | 20,62X33,32X33,32 | 20,62 | 33,32 | 33,32 | 4 |

| A122-022 | 22,22X34,92X19,05 | 22,22 | 34,92 | 19,05 | 4 |

| A122-028 | 28,57X41,27X22,22 | 28,57 | 41,27 | 22,22 | 4 |

| A122-031 | 31,75X44,45X25,4 | 31,75 | 44,45 | 25,4 | 4 |

| A122-038 | 38,1X50,8X25,4 | 38,1 | 50,8 | 25,4 | 4 |

| A122-038/1 | 38,1X53,98X25,4 | 38,1 | 53,98 | 25,4 | 6 |

| A122-044 | 44,45X57,15X25,4 | 44,45 | 57,15 | 25,4 | 4 |

| A122-044/1 | 44,45X63,5X38,1 | 44,45 | 63,5 | 38,1 | 6 |

| A122-044/2 | 44,45X69,85X50,8 | 44,45 | 69,85 | 50,8 | 8 |

| A122-044/3 | 44,45X60,33X30,15 | 44,45 | 60,33 | 30,15 | 6 |

| A122-050 | 50,8X63,5X25,4 | 50,8 | 63,5 | 25,4 | 4 |

| A122-050/1 | 50,8X65X25,4 | 50,8 | 65 | 25,4 | 4 |

| A122-050/2 | 50,8X66,67X25,4 | 50,8 | 66,67 | 25,4 | 6 |

| A122-050/3 | 50,8X69,85X25,4 | 50,8 | 69,85 | 25,4 | 6 |

| A122-050/4 | 50,8X69,85X28 | 50,8 | 69,85 | 28 | 6 |

| A122-053 | 53,98X69,85X28,5 | 53,98 | 69,85 | 28,5 | 6 |

| A122-057 | 57,16X76,2X25,4 | 57,16 | 76,2 | 25,4 | 6 |

| A122-063 | 63,5X76,2X28,5 | 63,5 | 76,2 | 28,5 | 4 |

| A122-063/1 | 63,5X78X41 | 63,5 | 78 | 41 | 4 |

| A122-063/2 | 63,5X79,37X28,5 | 63,5 | 79,37 | 28,5 | 6 |

| A122-063/3 | 63,5X82,55X28,5 | 63,5 | 82,55 | 28,5 | 6 |

| A122-069 | 69,85X88,9X31,75 | 69,85 | 88,9 | 31,75 | 6 |

| A122-069/1 | 69,85X82,55X31,75 | 69,85 | 82,55 | 31,75 | 4 |

| A122-076 | 76,2X88,9X25,4 | 76,2 | 88,9 | 25,4 | 4 |

| A122-076/1 | 76,2X95,25X31,75 | 76,2 | 95,25 | 31,75 | 6 |

| A122-076/2 | 76,2X101,6X38,1 | 76,2 | 101,6 | 38,1 | 8 |

| A122-082 | 82,55X101,6X31,75 | 82,55 | 101,6 | 31,75 | 6 |

| A122-088 | 88,9X104,8X28,5 | 88,9 | 104,8 | 28,5 | 6 |

| A122-088/1 | 88,9X107,95X30,16 | 88,9 | 107,95 | 30,16 | 6 |

| A122-088/2 | 88,9X114,3X38,1 | 88,9 | 114,3 | 38,1 | 8 |

| A122-095 | 95,25X114,3X30,16 | 95,25 | 114,3 | 30,16 | 6 |

| A122-101 | 101,6X127X38,1 | 101,6 | 127 | 38,1 | 8 |

| A122-107 | 107,95X127X31,75 | 107,95 | 127 | 31,75 | 6 |

| A122-107/1 | 107,95X130,18X38,1 | 107,95 | 130,18 | 38,1 | 6 |

| A122-114 | 114,3X133,36X31,75 | 114,3 | 133,36 | 31,75 | 6 |

| A122-114/1 | 114,3X139,7X38,1 | 114,3 | 139,7 | 38,1 | 8 |

| A122-127 | 127X158,75X60 | 127 | 158,75 | 60 | 8 |

| A122-152 | 152,4X177,8X33,3 | 152,4 | 177,8 | 33,3 | 8 |

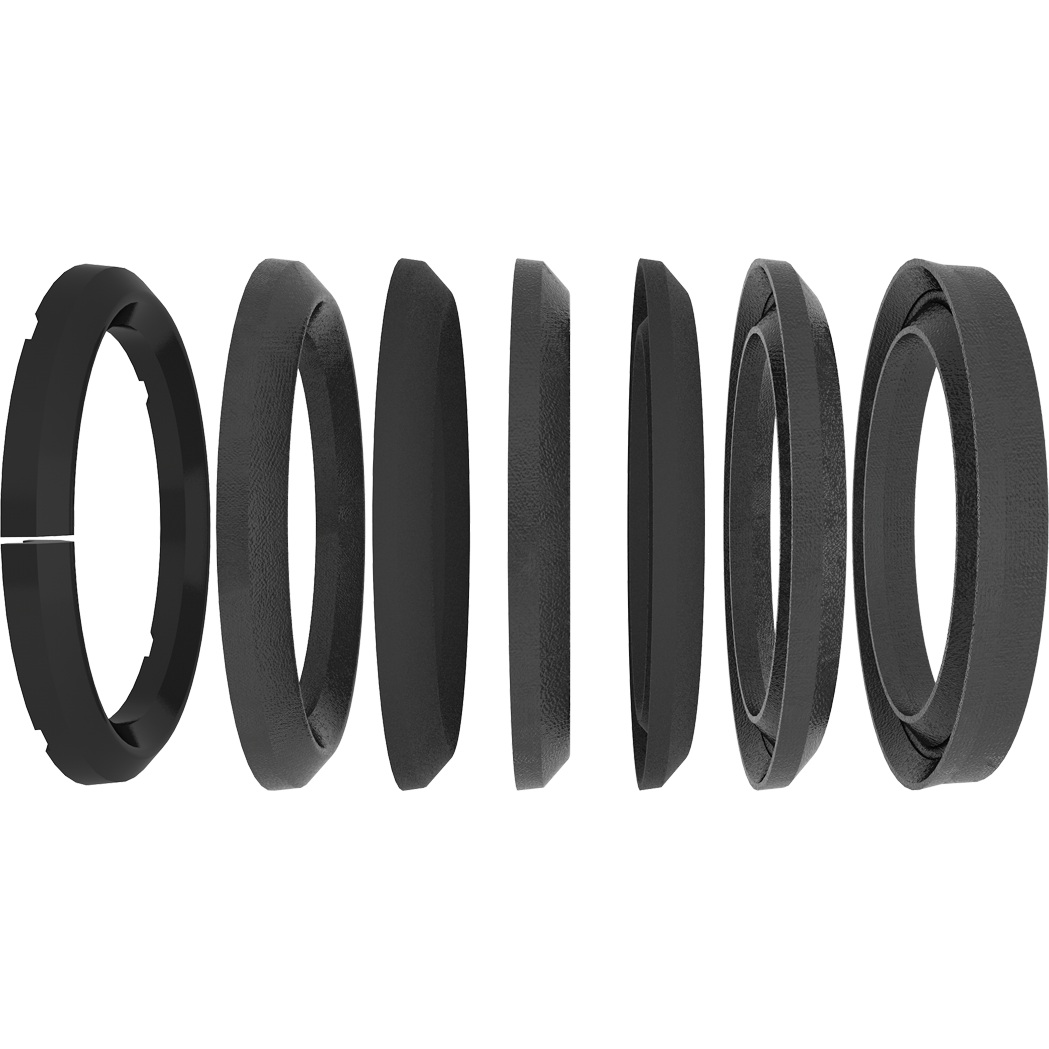

A122 Packings are made up of “V” shaped rings combination that are preformed and moulded with NBR applied on cotton fabric.

They consist of 7 elements in total which are 1 front POM ring, 3 fabriced NBR middle ring, 2 NBR middle ring and 1 fabriced NBR back ring.

These packings are recommended to be used in rod applications and be assembled to open seal housing. If the ratio between the ‘’B’’ height of open seal housing and total packing’s height is adjusted at %7.5, it offers easier usage. Its is not recommended to overpress the rings during assembly because it will lead to high friction.

| TECHNICAL DATA | |

| Working Pressure | 400 Bar |

| Working Temperature | -30 /+105°C |

| Sliding Speed | 0.5 m/sn |

| Material | 90 NBR / Fabric NBR / POM |

| Media | Mineral Base Hydraulic Oil |

| Surface Roughness | ||

| Ra | Rmax | |

| Dynamic Surface | ≤0.4 μm | ≤3.2 μm |

| Groove Base | ≤1.6 μm | ≤6.3 μm |

| Groove Flanks | ≤3.2 μm | ≤16.0 μm |

| Permissible Gap (Smax.) | |

| Working Pressure | S (mm) |

| P≤350 | 0.45 |

| 350<P≤600 | 0.25 |