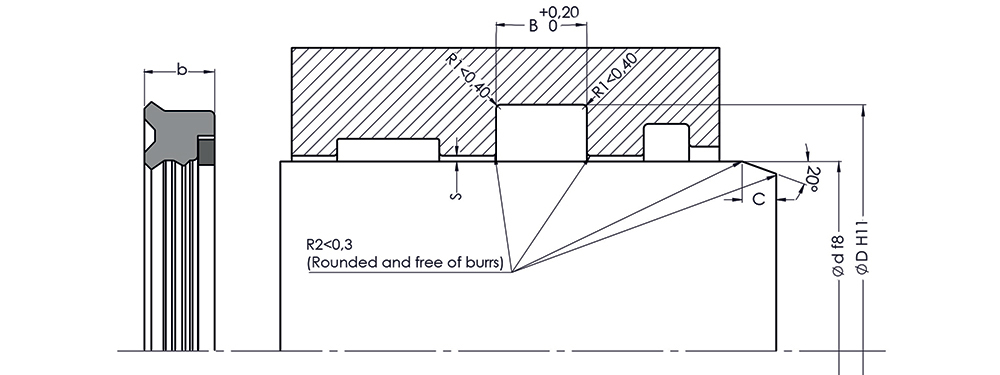

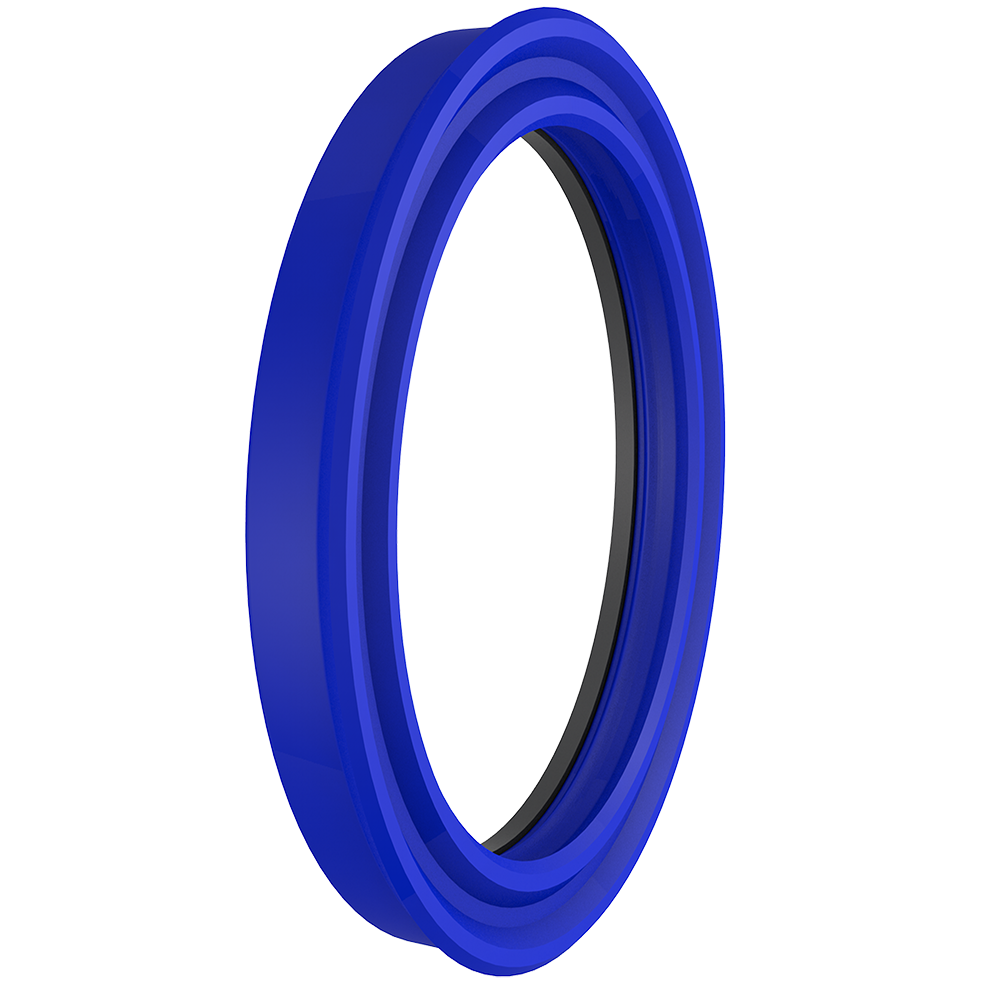

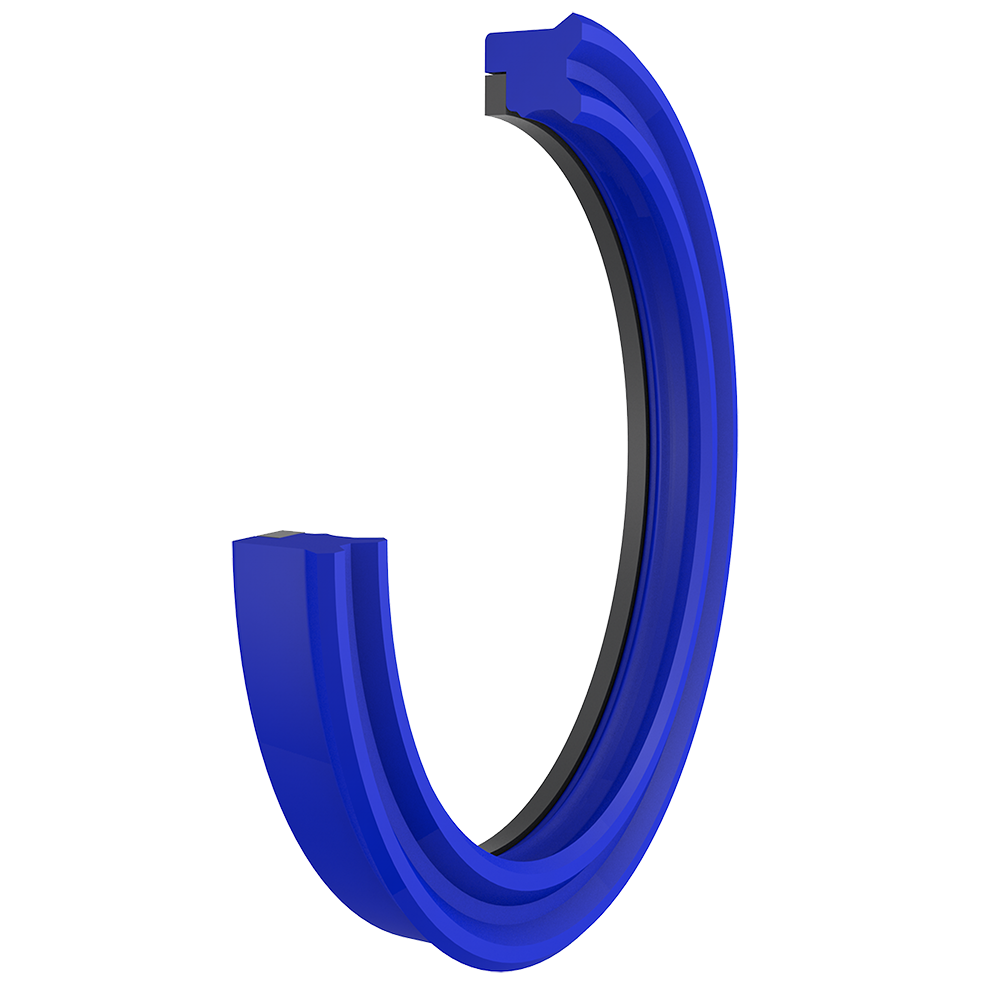

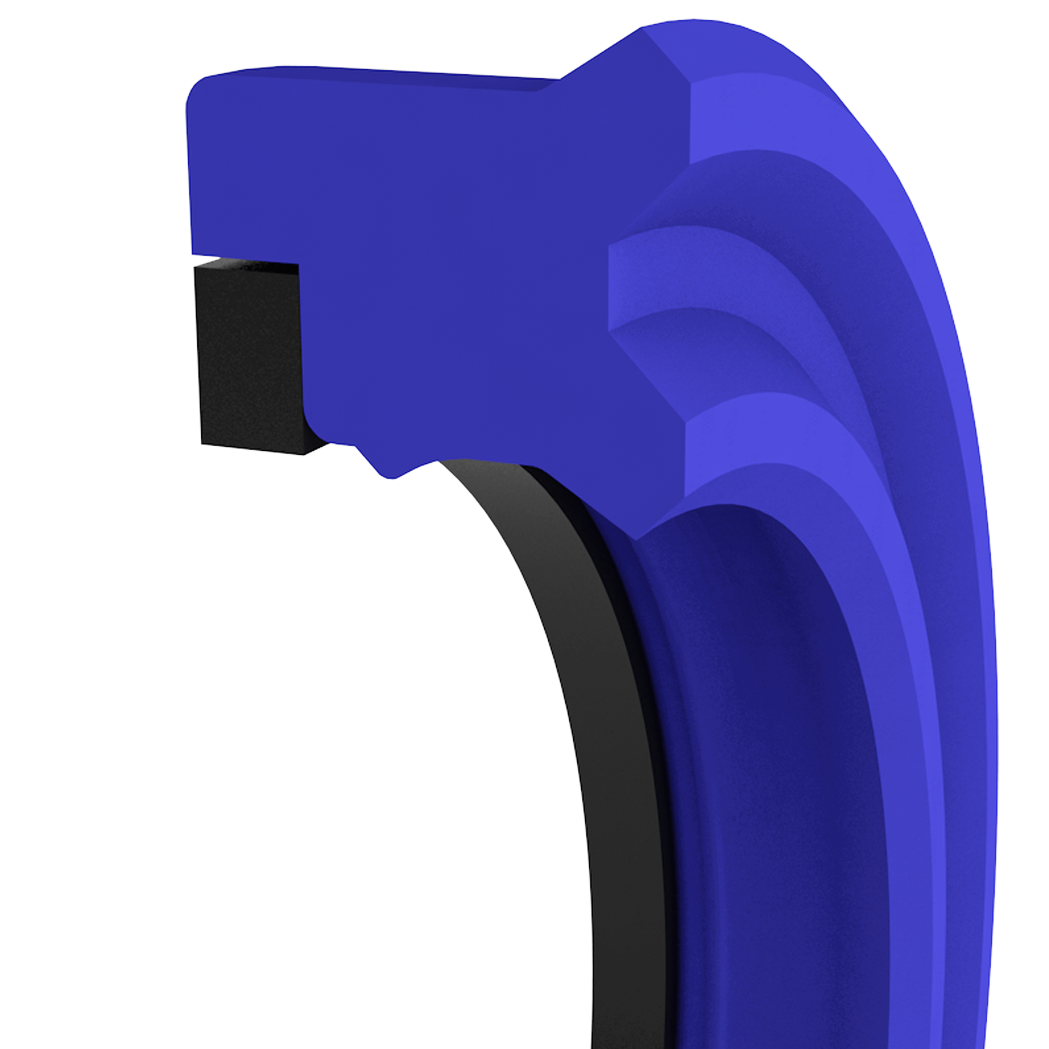

Our A187 nutrings are for rod applications. Thanks to the POM backup ring inside, it provides high extrusion resistance.

Due to its special lip form, it provides superior performance at low pressures.

Preferred in narrow grooves, A187 rod nutrings can be easily installed in closed grooves. Its second dynamic sealing lip leaves a lower oil film thickness, and at the same time prevents negative particles that may come from outside the system from entering the cylinder.

| TECHNICAL DATA |

| Working Pressure |

400 Bar |

| Working Temperature |

-40/+100°C |

| Sliding Speed |

0.5 m/sn |

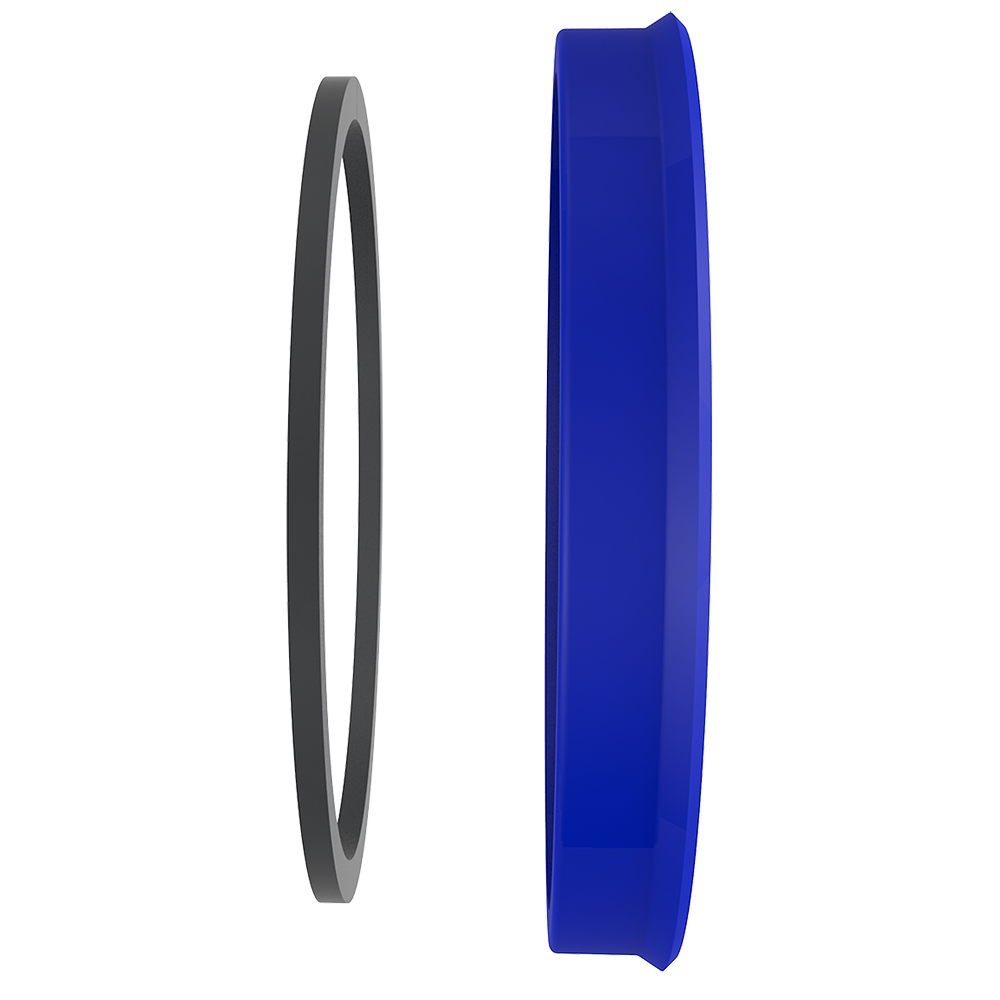

| Material |

92 PU / POM |

| Media |

Mineral Base Hydraulic Oil |

| Surface Roughness |

| |

Ra |

Rmax |

| Dynamic Surface |

≤0.4 μm |

≤3.2 μm |

| Groove Base |

≤1.6 μm |

≤10.0 μm |

| Groove Flanks |

≤3.2 μm |

≤16.0 μm |

| Permissible Gap (max.) for PU |

| |

Pressure (Bar) |

| 150 |

250 |

400 |

| S Max (mm) |

1.0 |

0.8 |

0.6 |