A406

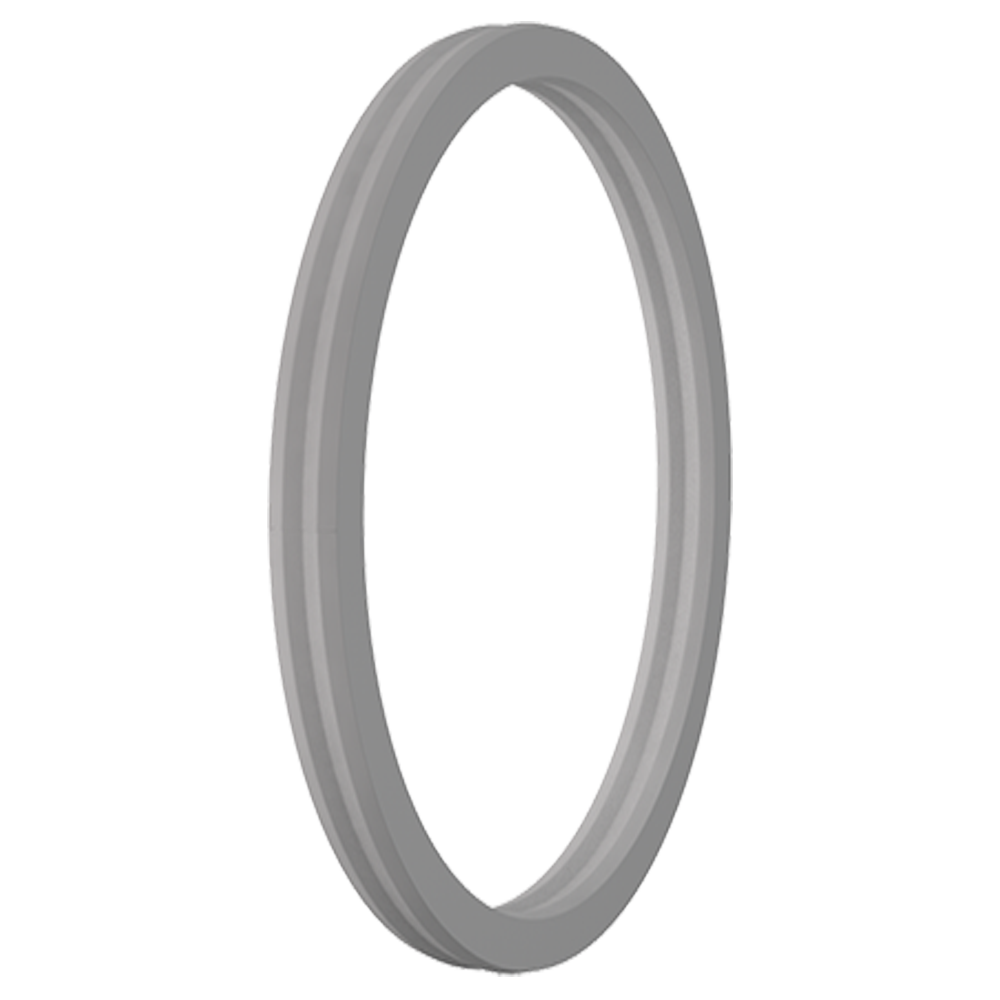

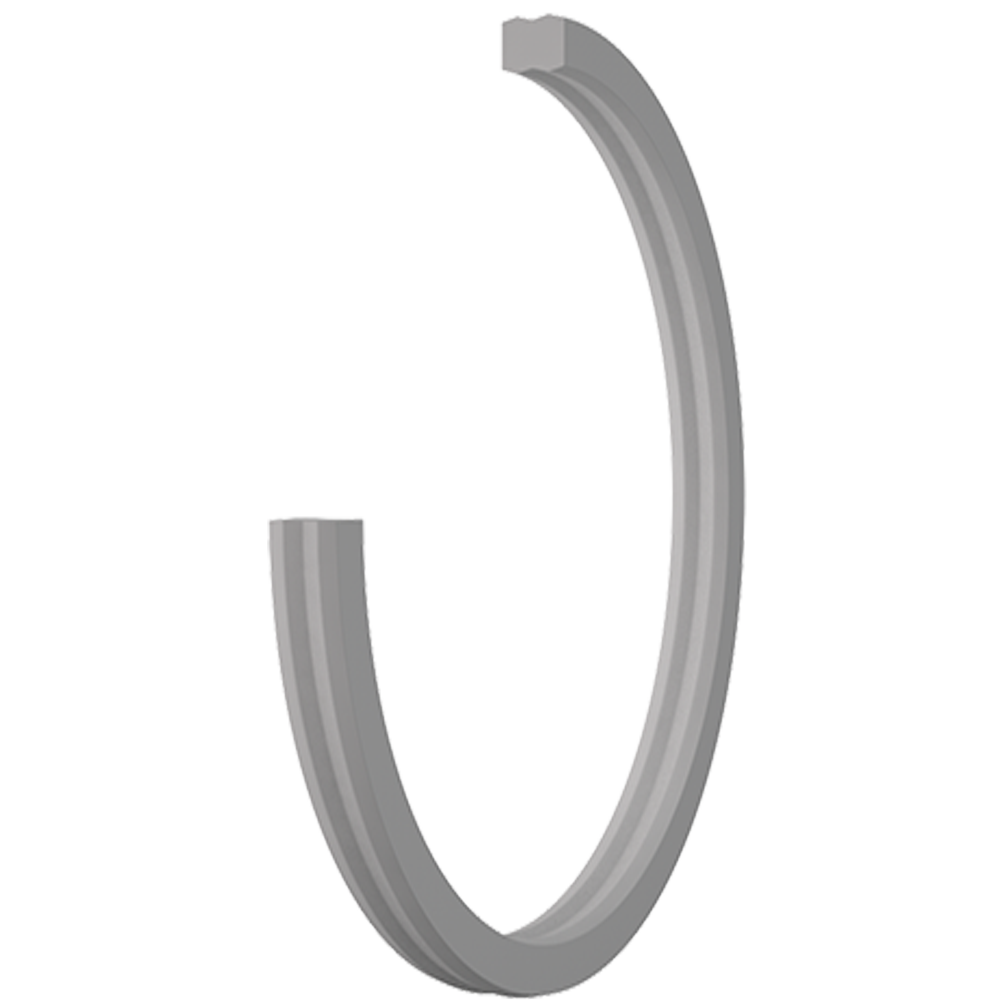

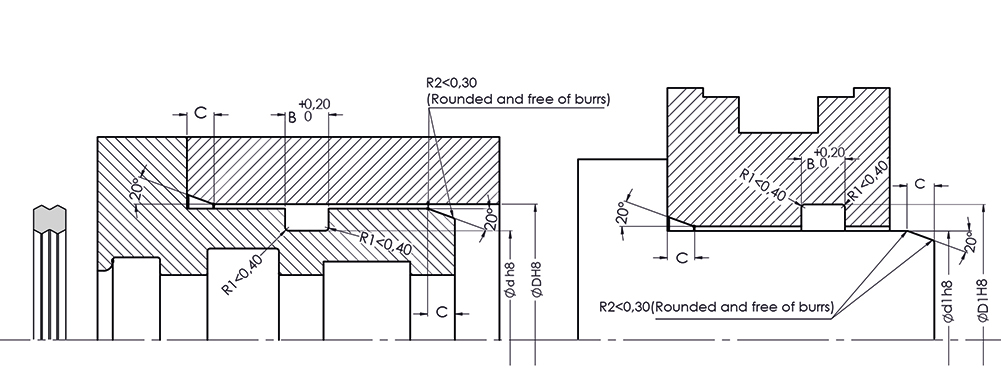

| ALP NO | DIMENSION | Ød | ØD | B | C | ØD1 | Ød1 |

|---|---|---|---|---|---|---|---|

| A406-030 | 30X25,5X4,5 | 25,5 | 30 | 4,5 | 2,5 | 29,5 | 25 |

| A406-030/2 | 30X26,2X3 | 26,2 | 30 | 3 | 2 | 29,8 | 26 |

| A406-031 | 31X26,4X3,9 | 26,4 | 31 | 3,9 | 2,5 | 30,6 | 26 |

| A406-035 | 35X30,5X4,5 | 30,5 | 35 | 4,5 | 2,5 | 34,5 | 30 |

| A406-040/2 | 40X34,5X4,5 | 34,5 | 40 | 4,5 | 3 | 39,5 | 34 |

| A406-041 | 41X36,4X3,9 | 36,4 | 41 | 3,9 | 2,5 | 40,6 | 36 |

| A406-050 | 50X45,4X5,4 | 45,4 | 50 | 5,4 | 2,5 | 49,6 | 45 |

| A406-051 | 51X45,5X4,5 | 45,5 | 51 | 4,5 | 3 | 50,5 | 45 |

| A406-061 | 61X55,5X4,5 | 55,5 | 61 | 4,5 | 3 | 60,5 | 55 |

| A406-064 | 64X58,5X4,5 | 58,5 | 64 | 4,5 | 3 | 63,5 | 58 |

| A406-071 | 71X65,5X4,5 | 65,5 | 71 | 4,5 | 3 | 70,5 | 65 |

| A406-076/1 | 76X70,5X4,5 | 70,5 | 76 | 4,5 | 3 | 75,5 | 70 |

| A406-080 | 80X74,4X5,3 | 74,4 | 80 | 5,3 | 3 | 79,6 | 74 |

| A406-081 | 81X74,7X5,2 | 74,7 | 81 | 5,2 | 4 | 80,3 | 74 |

| A406-086 | 86X81,5X4,5 | 81,5 | 86 | 4,5 | 2,5 | 84,5 | 80 |

| A406-090 | 90X84,4X4,8 | 84,4 | 90 | 4,8 | 3 | 89,6 | 84 |

| A406-091 | 91X84,7X5,2 | 84,7 | 91 | 5,2 | 4 | 90,3 | 84 |

| A406-100/3 | 100X90,6X7,1 | 90,6 | 100 | 7,1 | 5 | 99,4 | 90 |

| A406-111 | 111,4X105X5,5 | 105 | 111,4 | 5,5 | 4 | 110,4 | 104 |

| A406-116 | 116X108X6,5 | 108 | 116 | 6,5 | 4 | 115 | 107 |

| A406-120 | 120X111,4X9 | 111,4 | 120 | 9 | 5 | 118,6 | 110 |

| A406-121 | 121X113X6,5 | 113 | 121 | 6,5 | 4 | 120 | 112 |

| A406-131 | 131X121,1X7,8 | 121,1 | 131 | 7,8 | 5 | 129,9 | 120 |

| A406-141 | 141X131,1X7,8 | 131,1 | 141 | 7,8 | 5 | 139,9 | 130 |

| A406-180 | 180X171,6X8,5 | 171,6 | 180 | 8,5 | 5 | 178,4 | 170 |

| A406-200 | 200X191,6X8,5 | 191,6 | 200 | 8,5 | 5 | 198,4 | 190 |

Designed to replace the O-ring and the support ring combination in static applications, our A406 static seals are manufactured using our special high-performance PU material. By its design, the rotation problem encountered in O-ring assemblies is eliminated. A406 static sealing elements, which eliminate the need for support ring with its high yield strength material, can be produced in accordance with standard O-ring grooves.

| TECHNICAL DATA | |

| Working Pressure | 500 bar |

| Working Temperature | -35/+110°C |

| Material | 95 PU |

| Media | Mineral Base Hydraulic Oil |

| Surface Roughness | ||

| Ra | Rmax | |

| Working Surface | ≤0.8 μm | ≤3.2 μm |

| Groove Base | ≤1.6 μm | ≤6.3 μm |

| Groove Flanks | ≤6.3 μm | ≤16.0 μm |