A175

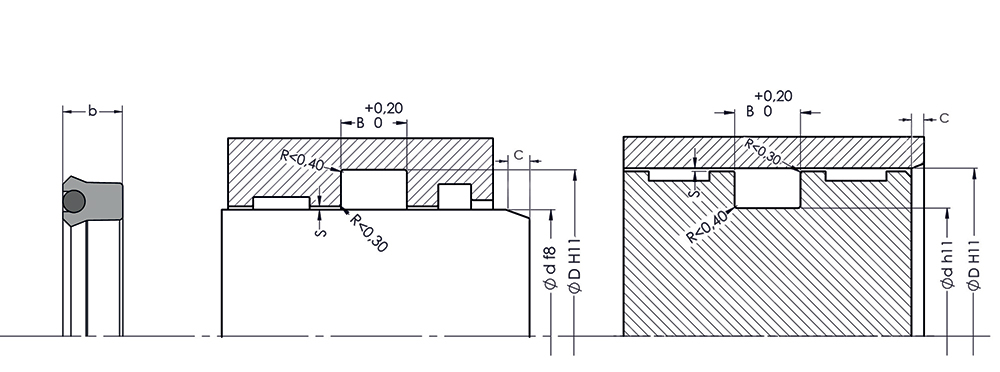

| ALP NO | DIMENSION | Ød | ØD | b | B | C |

|---|---|---|---|---|---|---|

| A175-019 PU | 19,05X25,4X6,35 | 19,05 | 25,4 | 6,35 | 6,98 | 3 |

| A175-022 PU | 22,23X28,58X3,18 | 22,23 | 28,58 | 3,18 | 3,51 | 3 |

| A175-025 PU | 25,4X31,75X6,35 | 25,4 | 31,75 | 6,35 | 6,98 | 3 |

| A175-025/1 PU | 25,4X34,93X4,76 | 25,4 | 34,93 | 4,76 | 5,28 | 4 |

| A175-025/2 PU | 25,4X34,93X7,94 | 25,4 | 34,93 | 7,94 | 8,71 | 4 |

| A175-025/3 PU | 25,4X38,1X6,35 | 25,4 | 38,1 | 6,35 | 6,98 | 4,5 |

| A175-028 PU | 28,58X38,1X4,76 | 28,58 | 38,1 | 4,76 | 5,28 | 4 |

| A175-028/1 PU | 28X40X9 | 28 | 40 | 9 | 10 | 4 |

| A175-030 PU | 30X40X6 | 30 | 40 | 6 | 7 | 4 |

| A175-030/1 PU | 30X40X9 | 30 | 40 | 9 | 10 | 4 |

| A175-031 PU | 31,75X38,1X6,35 | 31,75 | 38,1 | 6,35 | 6,98 | 3 |

| A175-031/1 PU | 31,75X41,28X7,94 | 31,75 | 41,28 | 7,94 | 8,71 | 4 |

| A175-038 PU | 38,1X47,63X7,94 | 38,1 | 47,63 | 7,94 | 8,71 | 4 |

| A175-038/1 PU | 38,1X47,63X9,53 | 38,1 | 47,63 | 9,53 | 10,49 | 4 |

| A175-038/2 PU | 38,1X50,8X9,53 | 38,1 | 50,8 | 9,53 | 10,49 | 4,5 |

| A175-040 PU | 40X50X6 | 40 | 50 | 6 | 7 | 4 |

| A175-044 PU | 44,45X53,98X9,53 | 44,45 | 53,98 | 9,53 | 10,49 | 4 |

| A175-047 PU | 47,62X57,15X9,52 | 47,62 | 57,15 | 9,52 | 10,48 | 4 |

| A175-050 PU | 50,8X60,33X9,53 | 50,8 | 60,33 | 9,53 | 10,49 | 4 |

| A175-050/1 PU | 50,8X63,5X9,53 | 50,8 | 63,5 | 9,53 | 10,49 | 4,5 |

| A175-057 PU | 57,15X69,85X6,35 | 57,15 | 69,85 | 6,35 | 6,98 | 4,5 |

| A175-063 PU | 63,5X76,2X9,53 | 63,5 | 76,2 | 9,53 | 10,49 | 4,5 |

| A175-076 PU | 76,2X88,9X9,53 | 76,2 | 88,9 | 9,53 | 10,49 | 4,5 |

| A175-076/1 PU | 76,2X95,25X15,875 | 76,2 | 95,25 | 15,875 | 17,47 | 5 |

| A175-088 PU | 88,9X101,6X9,53 | 88,9 | 101,6 | 9,53 | 10,49 | 4,5 |

| A175-092 PU | 92,08X101,6X9,53 | 92,08 | 101,6 | 9,53 | 10,49 | 4 |

| A175-105 PU | 105X120X9 | 105 | 120 | 9 | 10 | 4,5 |

| A175-107 PU | 107,95X127X15,88 | 107,95 | 127 | 15,88 | 17,47 | 5 |

| A175-109 PU | 109X125X10,5 | 109 | 125 | 10,5 | 11,5 | 4,5 |

| A175-152 PU | 152,4X171,45X15,875 | 152,4 | 171,45 | 15,875 | 17,47 | 5 |

A175 seals are designed to be used in both piston and rod applications.

Due to the O-Ring between the sealing lips, there is no in sealing performance loss under low pressures.

A175 seals have a design decrease reaction time of sealing lips during peak pressures or sudden changes.

Considering its special high performance series PU material, it can be used safely in heavy duty applications.

| TECHNICAL DATA | ||

| Working Pressure | 400 Bar | |

| Working Temperature | -30/+100°C | |

| Sliding Speed | 0.5 m/sn | |

| Material | 95 PU / 70 NBR | |

| Media | Mineral Base Hydraulic Oil | |

| Surface Roughness | ||

| Ra | Rmax | |

| Dynamic Surface | ≤0.4 μm | ≤3.2 μm |

| Groove Base | ≤1.6 μm | ≤10.0 μm |

| Groove Flanks | ≤3.2 μm | ≤16.0 μm |

| Permissible Gap (max.) | |||

| Cross Section | Pressure (Bar) | ||

| 150 | 250 | 400 | |

| ≤5 | 0.30 | 0.20 | 0.15 |

| >5 | 0.35 | 0.25 | 0.20 |