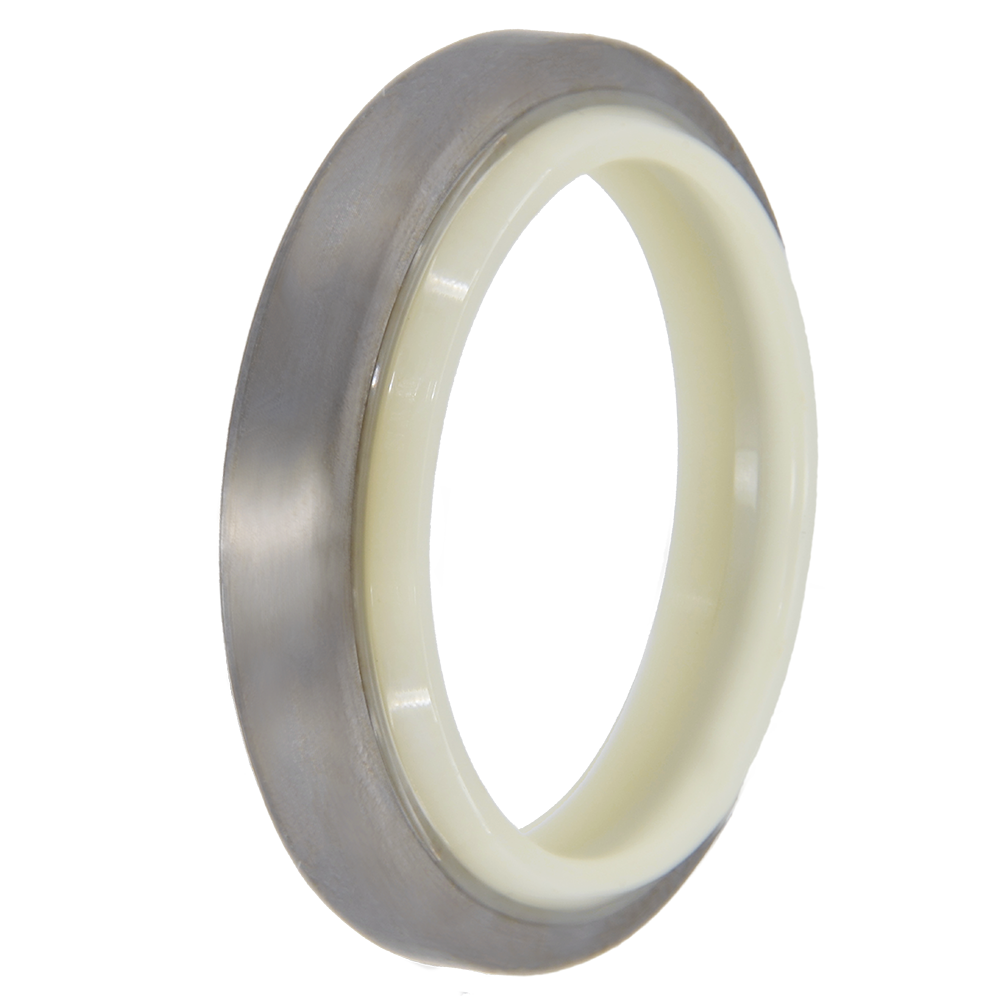

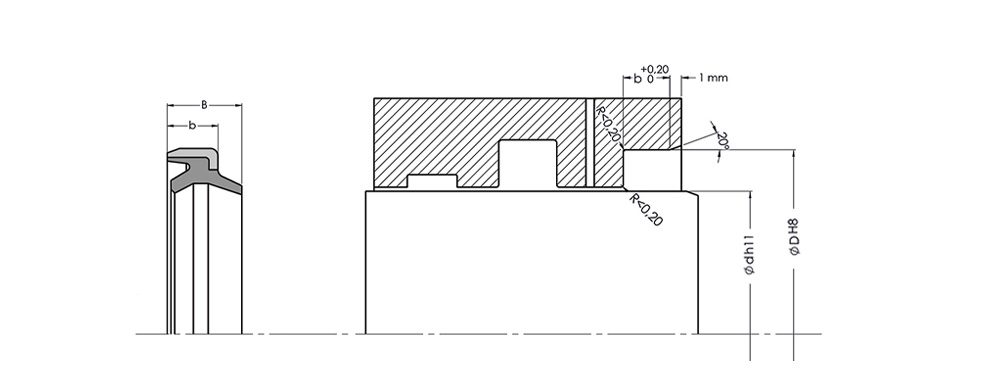

A207

| ALP NO | DIMENSION | Ød | ØD | b | B |

|---|---|---|---|---|---|

| A207-020 PU | 20X32X9/6 | 20 | 32 | 6 | 9 |

| A207-025 PU | 25X37X9/6 | 25 | 37 | 6 | 9 |

| A207-030 PU | 30X42X9/6 | 30 | 42 | 6 | 9 |

| A207-035 PU | 35X47X10/7 | 35 | 47 | 7 | 10 |

| A207-040 PU | 40X52X10/7 | 40 | 52 | 7 | 10 |

| A207-045/1 PU | 45X57X10/7 | 45 | 57 | 7 | 10 |

| A207-050 PU | 50X62X10/7 | 50 | 62 | 7 | 10 |

| A207-055/1 PU | 55X69X11/8 | 55 | 69 | 8 | 11 |

| A207-060 PU | 60X74X11/8 | 60 | 74 | 8 | 11 |

| A207-065 PU | 65X79X11/8 | 65 | 79 | 8 | 11 |

| A207-070 PU | 70X84X11/8 | 70 | 84 | 8 | 11 |

| A207-075 PU | 75X89X11/8 | 75 | 89 | 8 | 11 |

| A207-080 PU | 80X94X11/8 | 80 | 94 | 8 | 11 |

| A207-085 PU | 85X99X11/8 | 85 | 99 | 8 | 11 |

| A207-090 PU | 90X104X11/8 | 90 | 104 | 8 | 11 |

| A207-095 PU | 95X109X11/8 | 95 | 109 | 8 | 11 |

| A207-100 PU | 100X114X11/8 | 100 | 114 | 8 | 11 |

| A207-105 PU | 105X121X12/9 | 105 | 121 | 9 | 12 |

| A207-110 PU | 110X126X12/9 | 110 | 126 | 9 | 12 |

| A207-115 PU | 115X131X12/9 | 115 | 131 | 9 | 12 |

| A207-120 PU | 120X136X12/9 | 120 | 136 | 9 | 12 |

| A207-130 PU | 130X146X12/9 | 130 | 146 | 9 | 12 |

| A207-140 PU | 140X160X14/10 | 140 | 160 | 10 | 14 |

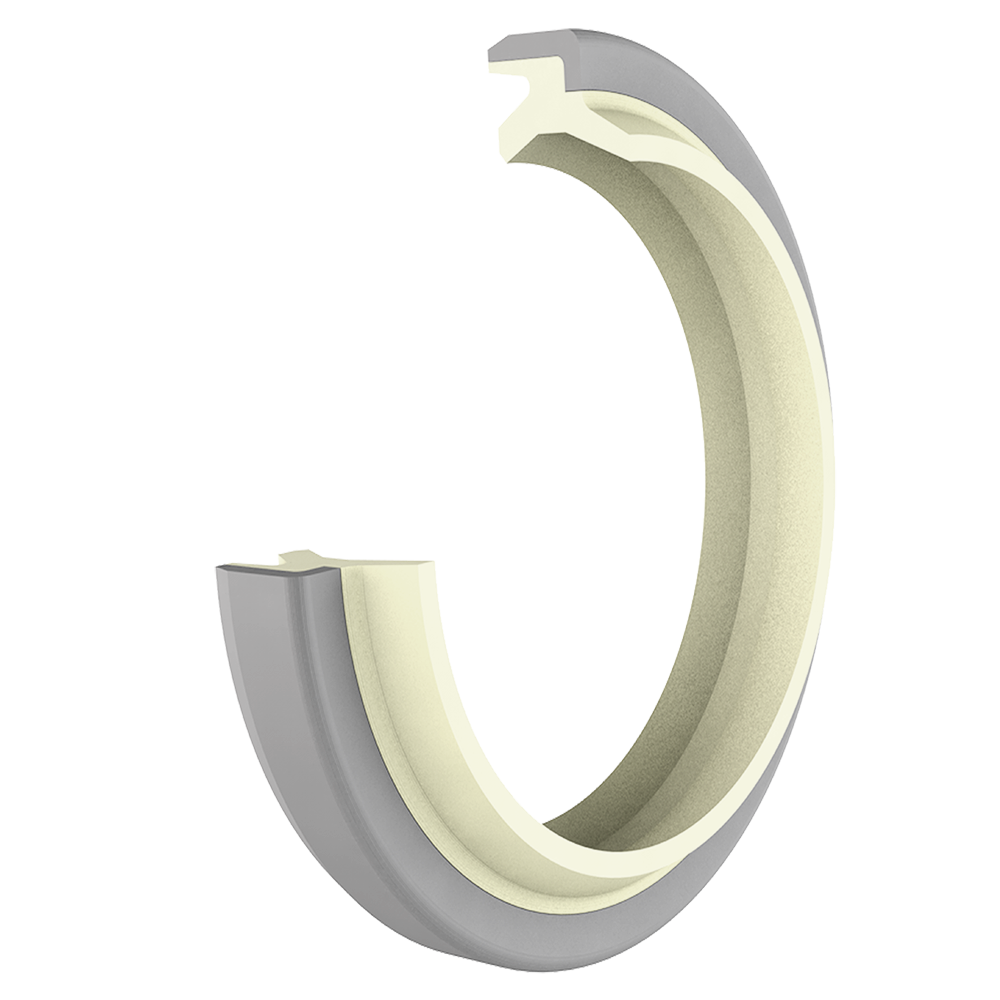

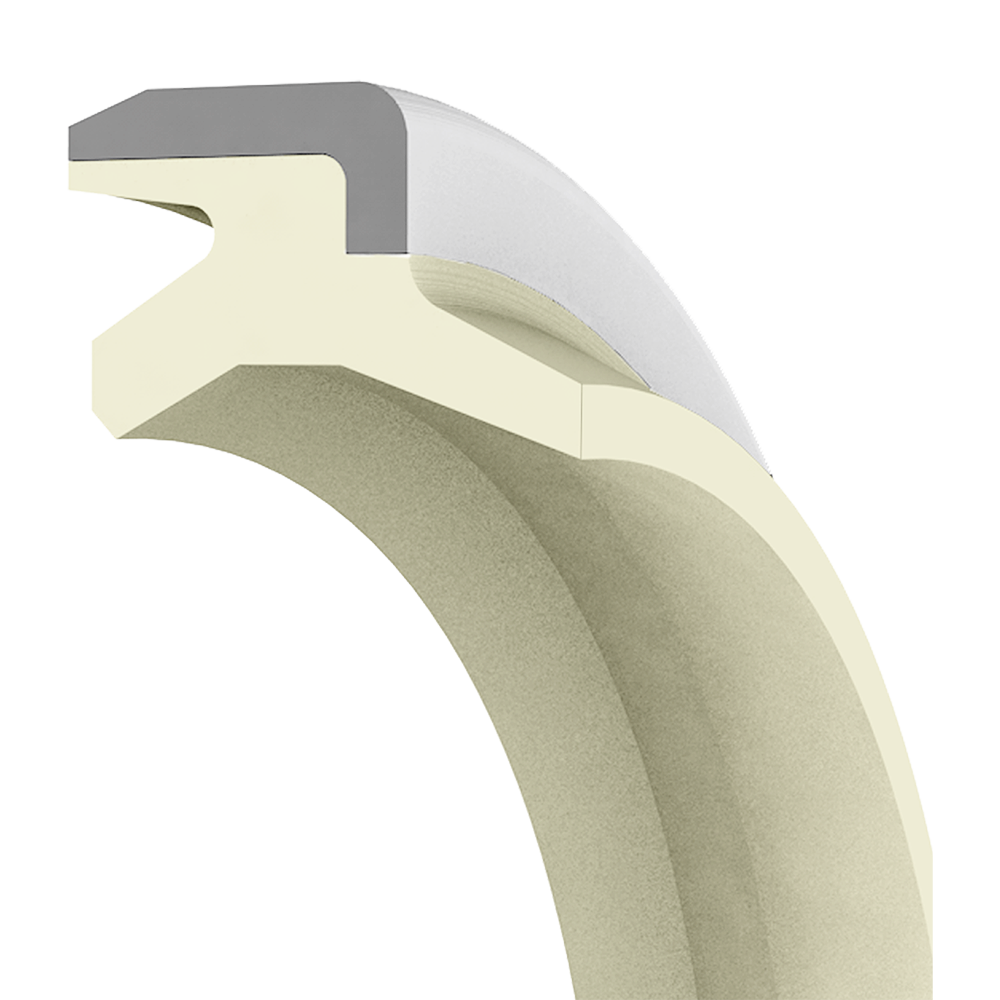

A207 Wipers with metal cases are used in order to prevent foreign particules from entering the system.

Special vulcanization processes are used during production. These seals are interference fitted into the groove. Proper tools should be used during assembly, so that seal and grooves will not be damage.

Nutring lips reduces oil film thickness on the rod. Pressure build-up occurs between rod seal and A207 Metal Cage Wiper. In order to prevent pushing the seal from housing, pressure relief solutions should be preferred.

| TECHNICAL DATA | |

| Working Temperature | -30/+100°C |

| Sliding Speed | 0.5 m/sn |

| Material | 92 PU / METAL |

| Surface Roughness | ||

| Ra | Rmax | |

| Dynamic Surface | ≤0.4 μm | ≤3.2 μm |

| Groove Base | ≤1.6 μm | ≤10.0 μm |

| Groove Flanks | ≤3.2 μm | ≤16.0 μm |