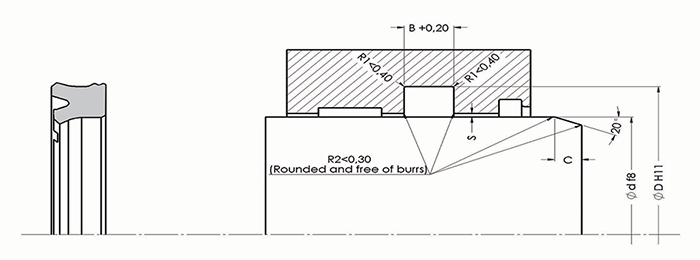

A181

| ALP NO | DIMENSION | Ød | ØD | B | C |

|---|---|---|---|---|---|

| A181-040 | 40X50X7 | 40 | 50 | 8 | 4,5 |

| A181-045 | 45X55X7 | 45 | 55 | 8 | 4,5 |

| A181-050 | 50X63X10 | 50 | 63 | 11 | 5 |

| A181-050/1 | 50X63X7 | 50 | 63 | 8 | 5 |

| A181-055 | 55X68X10 | 55 | 68 | 11 | 5 |

| A181-065 | 65X78X10 | 65 | 78 | 11 | 5 |

| A181-070 | 70X83X10 | 70 | 83 | 11 | 5 |

| A181-075 | 75X88X10 | 75 | 88 | 11 | 5 |

| A181-080 | 80X93X10 | 80 | 93 | 11 | 5 |

| A181-085 | 85X100X10 | 85 | 100 | 11 | 5,5 |

| A181-090 | 90X105X10 | 90 | 105 | 11 | 5,5 |

| A181-095 | 95X110X10,5 | 95 | 110 | 11,5 | 6 |

| A181-100 | 100X115X10 | 100 | 115 | 11 | 5,5 |

| A181-110 | 110X130X10 | 110 | 130 | 11 | 6 |

| A181-110/1 | 110X125X9 | 110 | 125 | 10 | 5,5 |

| A181-120 | 120X140X10 | 120 | 140 | 11 | 6 |

| A181-140 | 140X160X12 | 140 | 160 | 13 | 6 |

| A181-140/1 | 140X160X10 | 140 | 160 | 11 | 6 |

| A181-180 | 180X200X12 | 180 | 200 | 13 | 6 |

A181 sealing elements are produced with shorter inner lips to be used in rod applications.

Its special profile enhances static sealing performance. Standard A181 rod sealing elements are produced of NBR material and can be used under dirty and heavy conditions.

| TECHNICAL DATA | |

| Working Pressure | 160 Bar |

| Working Temperature | -30/+105°C |

| Sliding Speed | 0.5 m/sn |

| Material | 90 NBR |

| Media | Mineral Base Hydraulic Oil |

| Surface Roughness | ||

| Ra | Rmax | |

| Dynamic Surface | ≤0.4 μm | ≤3.2 μm |

| Groove Base | ≤1.8 μm | ≤10.0 μm |

| Groove Flanks | ≤3.0 μm | ≤16.0 μm |

| Permissible Gap (max.) for NBR | |||

| Cross Section | Pressure (Bar) | ||

| 50 | 100 | 160 | |

| ≤5 | 0.40 | 0.20 | 0.10 |

| >5 | 0.45 | 0.25 | 0.15 |